Submarine design typically follows American Bureau of Shipping (ABS) code, which establishes properties such as hull thickness, frame stiffness, porthole and hatch design and so on. During certification, ABS evaluates whether a design follows the relevant codes and then certifies it or not on that basis. But what happens when you have a submarine whose design is so unique that some ABS rules cannot be adhered to? That’s the situation Predictive Engineering encountered when the company was asked to get involved in the development of a deep-diving submarine commissioned by a private company.

The company had specific requirements for its vessel. First, it had to be capable of diving to a depth of 1,200 feet. That feature alone made it unique among privately owned submarines, most of which are tourist vessels that rarely go below 30 feet and are rated for a depth of 100 feet at most. Second, the company wanted extra large viewing ports, and along with them a sophisticated video imaging system with sufficient lighting to intimately observe the marine environment. Comfortable seating for ten passengers (including crew) was another requirement. In terms of performance, the submarine was to have a submerged endurance time of eight to 10 hours and emergency life support sufficient to sustain 10 adults for at least 72 hours. Finally, the weight of the submarine could not exceed the limitations of the existing surface support unit (a rather large yacht).

Building the finite element model

The design firm brought in Predictive Engineering, one of many finite element analysis companies, when the design was nearly finished. Knowing they had deviated some from ABS code, they wanted Predictive Engineering to virtually evaluate the performance of the submarine prior to construction and actual sea trials. Specifically, the analysis company was hired to predict global buckling behavior and local stress concentrations using finite element analysis (FEA) software.

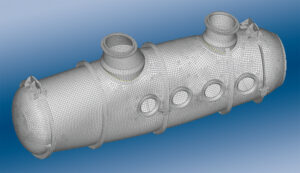

Creating the finite element model of the submarine was the first and most important task. Predictive Engineering was given CAD geometry representing the vessel. The geometry was in two formats: Pro/Engineer (the sub’s superstructure) and Autodesk Inventor (the hull skin, the hatches, view ports and their forgings). The Inventor data was a combination of surfaces and solids. The preprocessor, Femap software from Siemens PLM Software, had no trouble importing the different vendors’ formats. Also, once the data was imported, it didn’t matter whether it was surfaces or solids. Femap gave complete control over the initial geometry so that it could be set up exactly as the analysts needed for an accurate solution.

The model for predicting hull buckling and stress concentrations was particularly tricky. The analysts wanted to keep the size down so they could run multiple analysis iterations. Also, they had to deal with the disparity between the thin shell of the hull and the thicker, non-uniform forged structures such as the hatches and viewing ports. They constructed the model as a blend of 4-node plate elements (representing the hull’s skin and outer reinforcement rings) and 8-node brick elements (representing the forgings).

Small model permits many runs

This was a rather elegant modeling technique, but well within the capabilities of the preprocessor. “In fact, this is something Femap does better than any other code on the market,” says George Laird, president of Predictive Engineering. “Femap’s ability to merge different elements and modeling techniques was key to the speed and accuracy of this analysis.” The model ended up having approximately 67,000 nodes and 58,000 elements – extremely small by typical FEA standards and requiring a run time of about five minutes for the linear runs and 30 minutes for the geometrically non-linear buckling analyses using the Nastran solver.

Applying the pressure loads to this model was challenging as well. As a sub dives, it is under hydrostatic pressure, which means that the pressure field is completely balanced. If the forces over the whole sub are added up, the sum should be zero. Femap gave Predictive Engineering the tools to accurately apply the loads as well as tools to verify that when they summed the loads, they did actually come out to be zero.

The analysts made numerous analysis runs, always refining the model. Having such a small model was a big advantage because they could get such fast feedback. This is also a testament to the Nastran solver, which can solve a model containing a variety of element types quickly. In the analyses, Predictive Engineering took the submarine to well below the target depth of 1,200 feet. The results were ultimately verified against strain measurements made during a carefully validated dive test. (The strain measurements were taken using a fiber Bragg grating strain system.) In almost all cases, the strain measurements correlated well with the FEA predictions.

The finite element model, extensive FEA results and the experimental (strain gauge) data were sent to the ABS for certification. The organization accepted this data and certified the submarine based on this information. This is the first time Laird knows of that a submarine was certified solely on the basis of numerical methods instead of ABS code.