Considering First Mode’s initiatives and tight deadlines, a multi-phased approach was selected for their system implementation. Phase 1 was a 12-week project that covered the transition from Solid Works to NX in Teamcenter for all design personnel, and training in the US and Australia. Future phases will expand the footprint of the Teamcenter implementation into ELD, TCSIM, T4EA, Requirements, and Change Management.

Outline

Introducing First Mode

Objectives for PLM Implementation

How it Went

The Future

Introducing First Mode

First Mode is a global carbon reduction company that’s focused on heavy industry. Their goal is to decarbonize haulage in order to hit sustainability and greenhouse gas emissions standards.

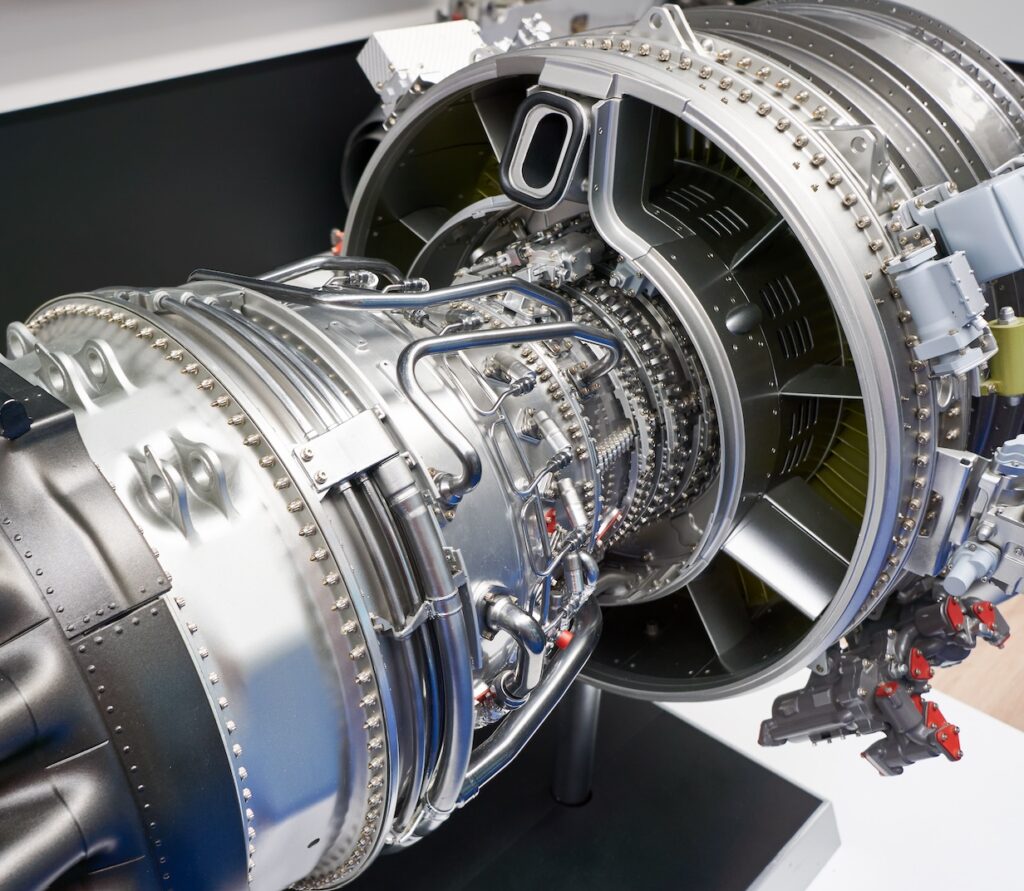

Their first task was to design and retrofit the world’s largest fuel-cell electric vehicle. The Mining haul truck in question was the diesel-fueled Komatsu 930E-4 ultra-class haul truck. Standing three stories tall, this massive truck weighs in at around 210 metric tons. Each of these trucks can carry 290 metric tons of ore. Retrofitting a single truck — one of the largest vehicles on the planet — with a power plant to run on hydrogen instead of diesel would reduce C02 emissions by 2,700 metric tons a year – the equivalent of taking 700 passenger cars off the road.

The challenge: to succeed, they needed to decarbonize not just the truck or the vehicle, but the entire diesel ecosystem around it also needed to be replaced — the truck, the fueling maintenance, and so on…all without missing a tonne.

First Mode has done just that, developing an end-to-end product and services that replace diesel. Not just the truck and the power system that goes into it, but how it gets the fuel and how the fuel gets produced as well.

Objectives for PLM Implementation

First Mode had several challenges they identified, revolving around the complexity of their product assemblies, the need for simulation, and multi-team collaboration.

Siemens NX was selected as the primary software tool for parts and assembly design. From past experience, the team knew they needed the right CAD tools, capable of modeling complex assemblies. Their previous tool was costing them precious time that was estimated about approximately two hours per user, per week, for crashes and loading times.

Leveraging the Siemens Xcelerator portfolio and digital twins to design, model, and simulate their designs, they also knew they needed a single source of truth for their design data. In addition, with offices all over the globe, a platform that could support collaboration regardless of time and location.

Teamcenter was selected as their PLM system. First Mode partnered with Applied CAx a platinum Siemens partnth specializing in Teamcenter PLM, NX, and simulation.

However, as a startup, they still had obstacles to overcome. Setting up a PLM, creating processe and deciding on requirements, with numerous stakeholders that had to be won over.

The PLM Services team with Applied consulted with the First Mode PLM implementation team throughout the implementation process, configuring their PLM to fit their needs, and making recommendations throughout their PLM Journey.

How it went

Having worked with a range of new startups, Applied CAx is experienced with the challenges new companies face.

Determining requirements, evolving workflows, and business practices takes time. These initial conversations can take months, followed by data migrations, and more. In addition, First Mode had an understaffed IT team, busy stakeholders, and the need to start designing in NX immediately for the flagship project.

To expedite this process for their customers, Applied developed a PLM implementation package referred to as Basic Essentials. Focused on reducing the timelines for PLM adoption, Applied’s Agile Deployment Options are flexible, allowing the adoption of later modules and expansion as needed. Applied’s PLM team worked hand in hand with Barron and the PLM implementation team at First Mode, configuring the PLM environment to their needs, while also winning the hearts and minds of the individual teams for user adoption.

At the same time, the users needed to be ready to start modeling in NX, so a series of CAD trainings were scheduled in the US and in Australia.

From creating and maintaining a full-size, mirrored test environment, to adopting cloud hosting, the Applied team demonstrated their commitment to the project, evening joining the Slack channel so they could advise and communicate in real-time.

Future plans and challenges

In closing, Barron outlines First Mode’s plans for further leveraging Siemens Teamcenter products, including the implementation of engineering change notices, problem reports, configuration management, and Manufacturing Bill of Materials (MBOMs). These initiatives reflect the company’s commitment to continuous improvement and an increased focus on production-oriented processes. Additionally, First Mode expresses its intention to explore cryogenic gas simulations using STAR-CCM and expand its collaboration into the electrical department.

First Mode’s experiences and plans exemplify their commitment to innovation, continuous improvement, and providing cutting-edge solutions in the field of engineering design. Applied CAx is proud to be a partner in their digital transformation journey.

Leveraging Siemens Products for a Better Tomorrow: First Mode PLM Implementation Story

Initially presented at Realize LIVE on June 15th, 2023.

Presented by:

Barron Knigge, Senior Electrical Engineer and PLM Implementation Lead — First Mode

Jesse Binford, Teamcenter Architect — Applied CAx