We are thrilled to welcome Jeff Churchey to our Digital Innovation Services Team as a Senior PLM Engineer! He has 16 years of industry experience, spanning the Aerospace & Defense and Energy industries. As a mechanical systems designer using Teamcenter managed NX, he supported a variety of special-mission aircraft design programs with L3Harris and developed cutting edge permanent magnet motors for oil production at Baker Hughes. For the past 6 years he’s changed career focus to Siemens application support and business process management, successfully deploying Siemens tools including Teamcenter, NX and Capital Harness for aerospace development programs.

Get to know Jeff

Q. What inspired you to join the Applied team?

A. Working as a Teamcenter architect for the past 6 years, I’ve spent a lot of time in Siemens’ community forums learning about Teamcenter, seeking help and sharing tips. I’ve seen Jamie Griffis’ contributions to the forums enough (likely many dozens of times) to know that she’s one of the most knowledgeable Teamcenter architects in the industry. When a recruiter reached out with the opportunity to join her team it seemed like a great opportunity to work with & learn from some of the best minds in the field.

Q. What are your areas of expertise?

A. From my tenure in product design:

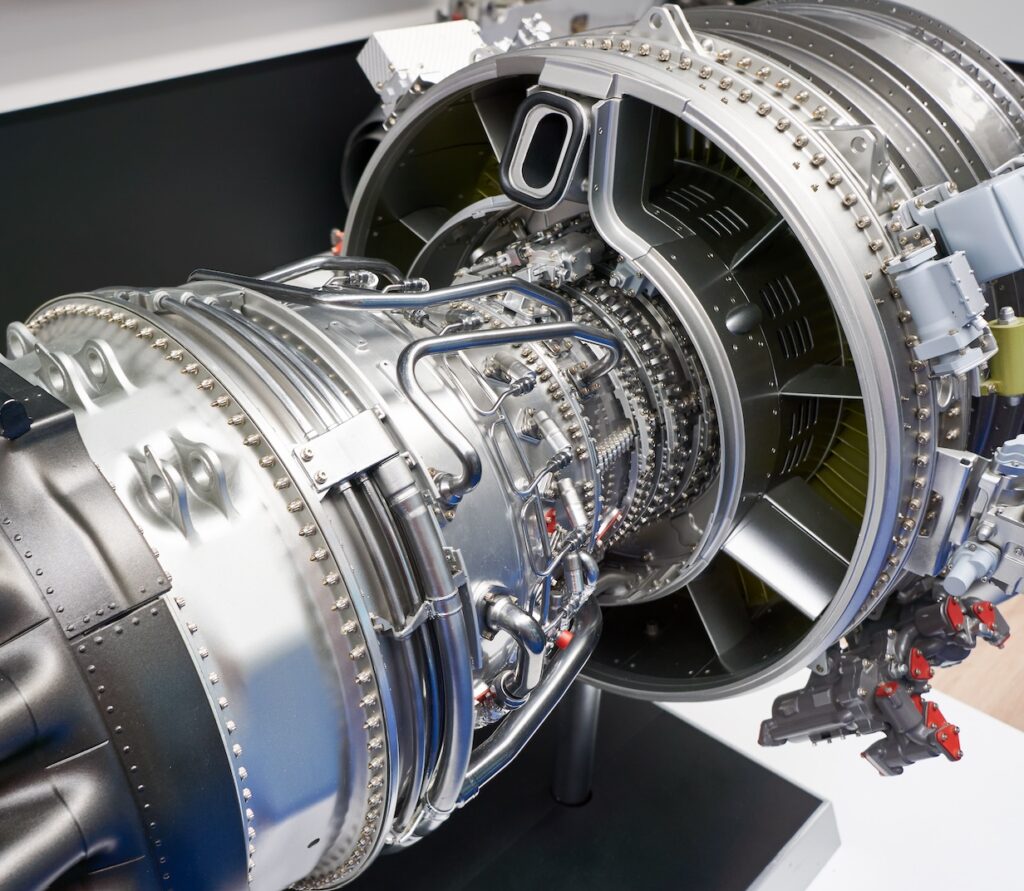

- Special missions aircraft development, including fuel/inflight refueling, hydraulic system design, aircraft cooling system design, and flight control systems.

- High voltage, ruggedized oil pump motor system design.

From my current role in Siemens application support:

- Teamcenter deployment planning & implementation

- Capital/NX/Teamcenter integration

- Teamcenter document management

- Client deployments/Powershell deployment scripting

Q. What do you do for Applied?

I’ll be working with the Applied team to manage Teamcenter environment configuration, development, and deployment for our customers.

A. Tell us about yourself – what’s your background and education?

I graduated in 2008 with a degree in mechanical engineering from Oklahoma State University. I spent my time at OSU trying to get as much hands-on experience in the field of mechanical engineering as possible by leading OSU’s Formula SAE team in the design & fabrication of a 1/3 scale Formula 1 race car.

This allowed me to get experience with all the equipment/processes (mills, lathes, welders, fiberglass composite layup, etc.) that would be used to translate the vehicle design from CAD to reality before I graduated college, which was incredibly valuable in my career moving forward.

Q. How did you get started in your field? What excited you about it?

A. With regard to engineering in general – I began taking mechanical things apart at a fairly young age (around 10 years old) which naturally developed to an interest in cars once I began driving. Mechanical things always interested me and I had a knack for fixing or improving them. By the time I graduated high school I knew I wanted to pursue a career in either automotive or aerospace design, and did exactly that for roughly 10 years after graduating college.

I got started supporting Siemens application by chance. I hired into a new job as a lead aircraft designer, and my new company happened to be standing up their first Teamcenter environment. Nobody at the company had ever used Teamcenter before, and they were struggling make the right decisions/make progress implementing. At this time I’d been using Siemens and NX for about 10 years, so had a good working knowledge of the end-user facing elements of the tools. I took ownership of the implementation and learned how to administer the back end of the system, while also serving as the lead engineer for external aircraft mod design. After roughly 9 months supporting both design and administrative roles, I transitioned into PLM support full-time.

Q. Where are you located?

A. About 30 minutes east of Tulsa, Oklahoma

Q. Where would we find you when you’re not at work?

A. I spend as much time as possible doing Cub Scouting or karate activities with my three sons (age 10, 7, and 4). When the kids don’t have activities lined up, I’m usually still working in one area or another…I’ve got experience in general construction, welding, woodworking, setting up home and business networks, etc. Whether for personal or volunteer projects, I stay fairly busy outside of work.

Q. If you could only eat one meal for the rest of your life, what would it be?

A. Probably tacos, since there are plenty of options for breakfast, lunch & dinner.

Q. Three fun facts about yourself:

- I recently earned my orange belt in karate.

- I’m learning Arduino programming with my 7 year old son to build a robot project this summer.

- I’m currently in the process of restoring 1978 Ford F150 with my sons, hoping for it to serve as their “learning” vehicle when they get to driving age.