- Optical frame for high-speed manufacturing line

- Food Processing Shaker Bed

- Airborn optical turret with Kaman bearing system

- Motor home frame

- 3,000 HP transmission for the oil and gas industry

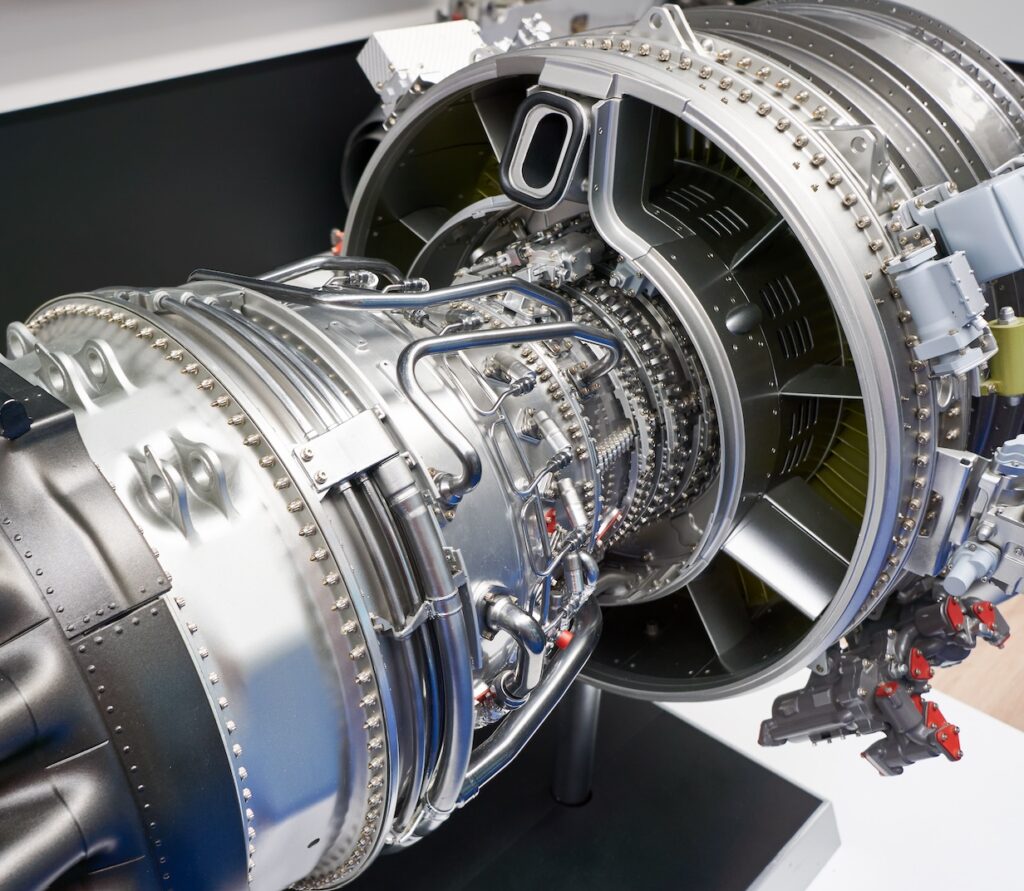

Figure 1: Normal modes, frequency analysis and transient dynamic analysis were applied to the design of novel vibrating conveyor systems. Predictive Engineering was able to provide “first time” correlation with experimental results. Analysis work laid the foundation for wide-spread adoption of FEA based vibration simulation at Key Technology. This partnership continues today with follow-on coaching and training.

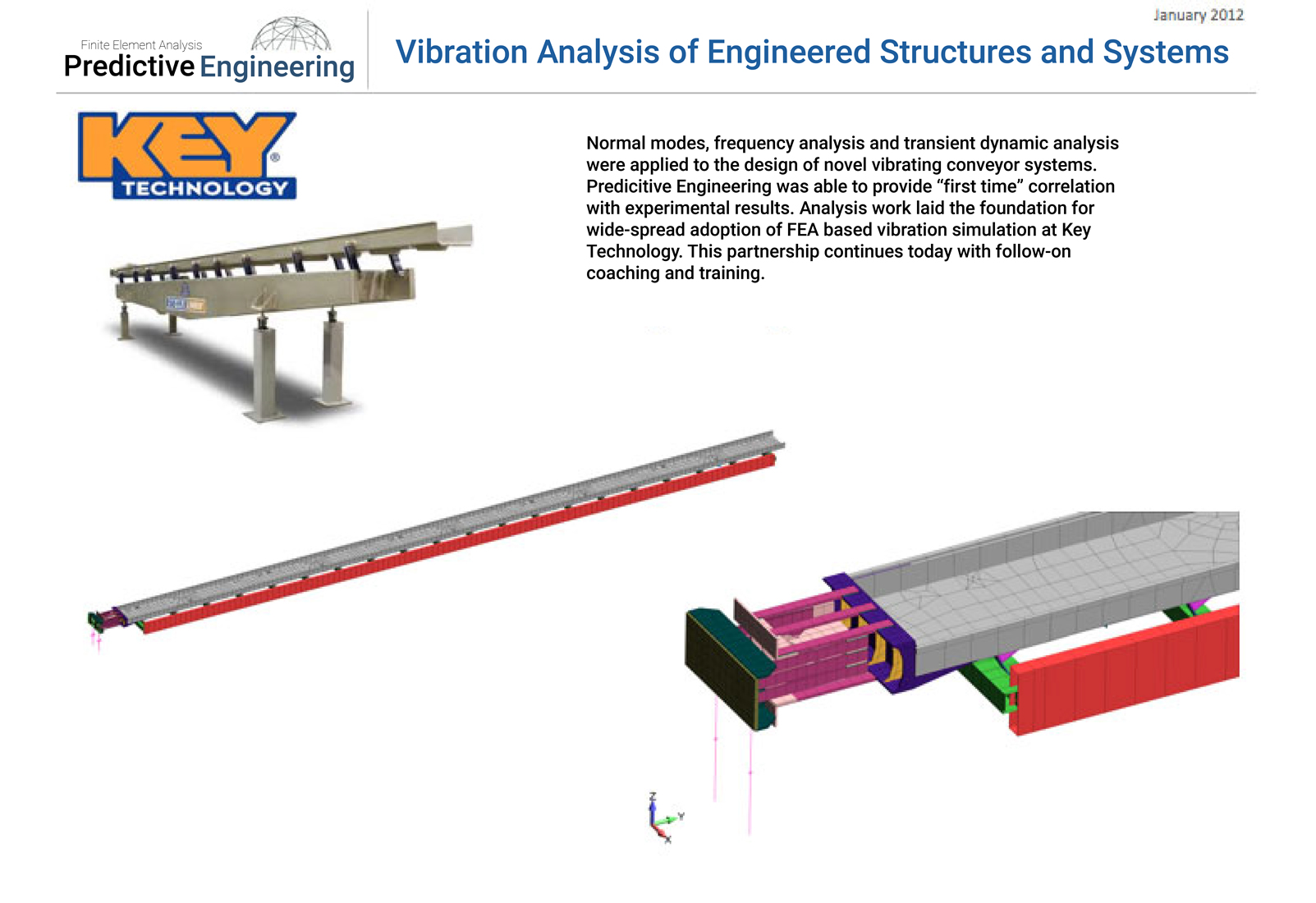

Figure 2: Normal modes analysis was performed on a series of driveshaft and cold-spinning motor testers. Each model was blind benchmarked against experimental data and found to be within 4 to 8% of experimental data. Analysis work was used to document new designs to up-stream clients and to obtain approval for large-scale manufacturing implementation.

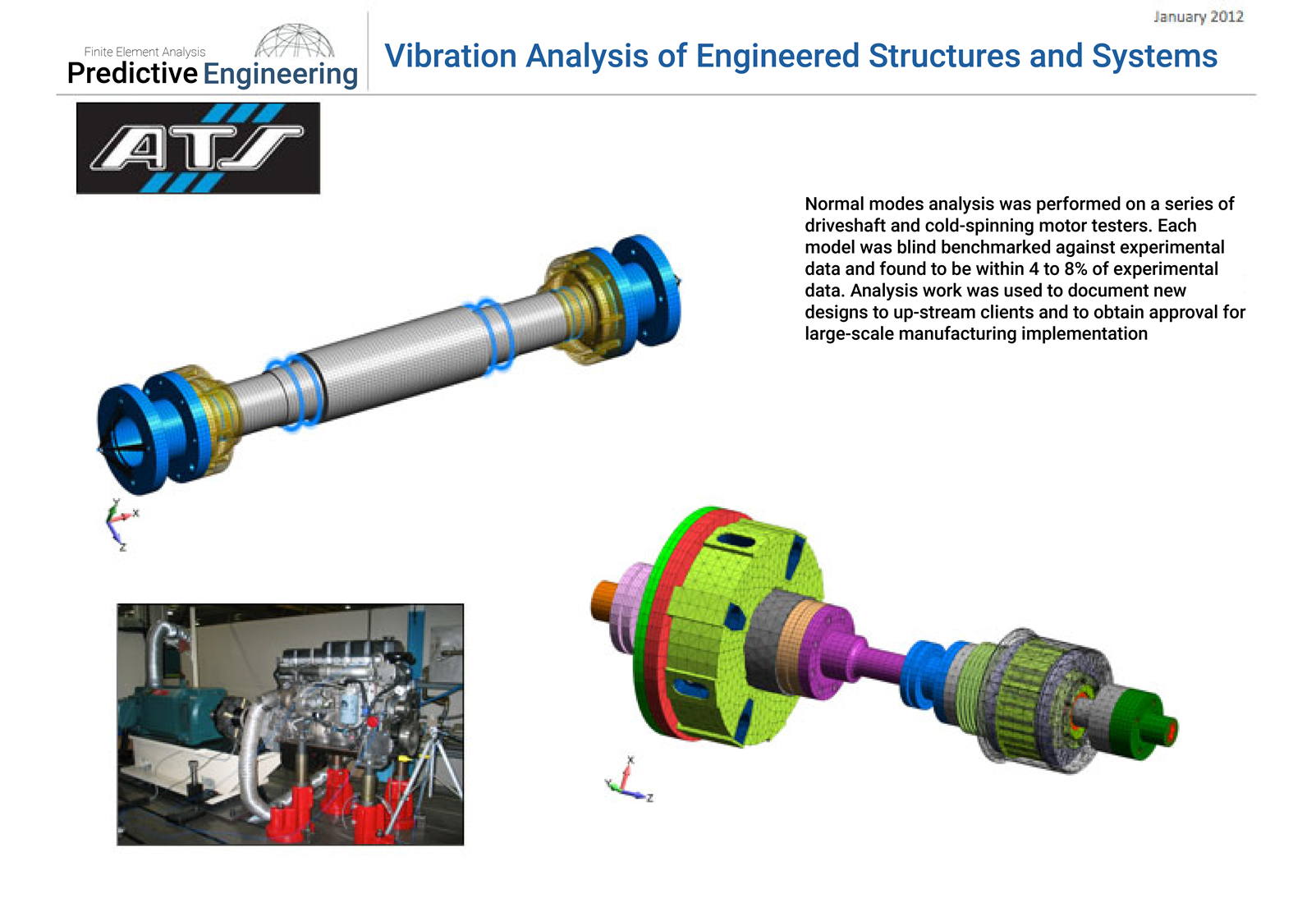

Figure 3: Although the normal modes analysis of single component structures or glued-together assemblies is routine, these models required exacting precision due to their high-technology requirement as part of an electron microscope. Vibration work was validated against experimental measurements and found to be within 3 to 5%. Analysis work allowed the client to proceed to manufacturing with no further testing.

Figure 4: Assembly line equipment for the optical inspection of LED panels. The frame structures held the panels while they were optically scanned. The camera movement created random vibrations within the frame that affected the image quality. Normal modes and frequency analysis work led to improved designs that allowed faster line speed while improving image quality.

Figure 5: Aviation hardware presents special challenges due to an exacting and demanding service environment. Normal modes and frequency sweep analysis work has been validated against shaker table work on several occasions. A key challenge on this project was incorporating the Kaman bearing stiffness into the turret. Project work continues to this day with follow-on work with thermal and drop-testing analyses.

Figure 6: Normal modes analysis using Femap and NX Nastran verified that road noise was contributing to the vibration behavior of this motor home coach frame. A NVH study further indicated that high-frequency modes were present within the steel frame that tended to be excited by motor and drive train noise. The Femap model was built with beam, plate, RBE and mass elements. The mass of the coach was balanced by using appropriately sized mass elements for the diesel motor, transmission, air conditioners and human occupants.

Figure 7: Structural and modal analysis optimization of a large 3,000 HP transmission for the oil and gas industry. The Femap model had 2.5 million nodes and was analyzed using a nonlinear normal modes solution sequence to correctly capture the transmission housing stiffness. Analysis results allowed the client to meet stringent natural frequency requirements while maintaining a lightweight and cost-efficient structure.